Applications

Robotic MIG/TIG Welding

FabX Automation delivers fully integrated robotic MIG and TIG weld cells that combine multi-axis manipulators, adaptive torch control, and real-time weld data capture. Guide Engineering, Advanced Welding Automation, Arc Solutions, and ARC Robotics each offer turnkey packages that boost deposition rates, reduce rework, and provide full traceability.

We provide both fully custom custom weld cells, and pre-engineered systems with low lead times, and ready for your tooling.

Available From:

High Volume Assembly Lines

Guide Engineering designs and builds multi station assembly lines which can include operations such as pressing, fastening, marking, welding and testing. In addition we can include data analytics along the assembly line with MES connectivity to ensure zero-defect throughput and verifiable cycle-time gains.

Available From:

Vision Guidance & Inspection

Automation grade cameras and laser profilometers direct robots for part handling, welding, and inspection. Guide Engineering and Advanced Welding Automation embed these vision cells to close the loop between process and quality in real time.

Available From:

Robotic Integrations

FabX Automation provides full robotic integrations, utilizing the latest technology on the market. This could include 3D vision picking, part handling, part processing or machine tending. We are capable of building turnkey solutions, or upscaling your existing equipment to reduce operator headcount.

Available From:

Manual Laser Welding

Advanced Welding Automation’s laser-robot platforms pair micron-accurate beam delivery with multi-axis part positioning to produce cosmetically clean, distortion-free welds on complex geometries and high-value alloys.

Available From:

Robotic Laser Welding

Advanced Welding Automation couples high-power fiber lasers with multi-axis robot arms and precision rotary tables to generate cosmetically perfect seams at production speed. Real-time seam tracking and adaptive power control eliminate burn-through on thin sections, while integrated fume extraction maintains a clean work envelope.

ARC Robotics supports larger envelopes by adding head-stock/tail-stock positioners for oversized frames, giving customers a single source for both micro- and macro-scale laser welding requirements

Available From:

Material Handling

In addition to our robotic integration, we are also capable of providing manual, semi automatic and fully automatic hard automation. Which could include loading conveyor-based,Integrated lift-assist to machinery, servo positioners, operator ergonomic handling of incoming components. This aids in reducing takt time, safeguarding both product quality and operator safety.

Available From:

Sealant, Grease, Oil and Adhesive Dispensing

We have experience in automating dispensing applications. We have used a variety of methods including metering pumps, transducer, pressure vs. time and servo applications. We are capable of applying RTV, Oil, Grease, Ceramic or other substrates joints, flanges, and housings.

In addition, on-the-fly inspection can be incorporated for bead-width monitoring, and closed-loop pressure control eliminates hand-applied variability, ensuring leak-proof assemblies. Dispense paths are programmable, eliminating changeover time when part geometries vary.

Available From:

Rotary and Seam Welding

Rotary turntables and Ferris-wheel fixtures enable continuous 360° seam welds on cylindrical or ring-shaped parts without repositioning. Servo-driven spindles synchronize weld speed with the arc or laser to guarantee uniform penetration. This approach boosts throughput and eliminates overlap defects common in multi-pass welds.

Available From:

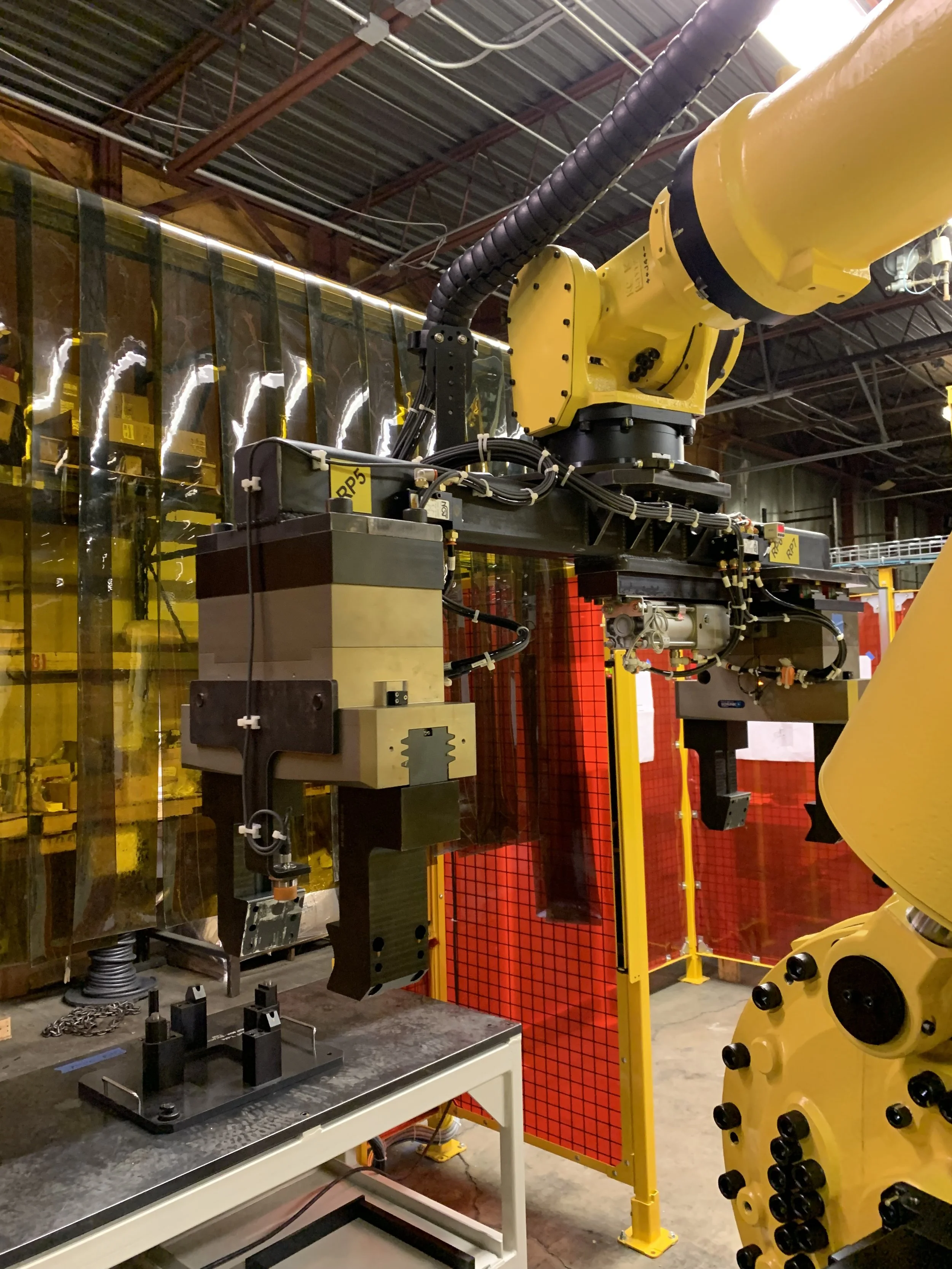

Robotic End-of-Arm Tooling

FabX engineers build custom robotic grippers, which can include servo control, pneumatic clamping, in gripper inspection or compliance devices. In applications with multiple part variants we can incorporate quick-change couplings to allow a single robot to change end effectors as necessary, maximizing cell flexibility.

Available From:

Pressing Systems w/ Analytics

We build Servo and hydraulic presses, rated up to 600 KN. We have experience in seating bearings, bushings, shafts and seals with programmable force-displacement profiles. Embedded load cells capture every press cycle, feeding pass/fail logic to plant-wide quality systems. During the pressing operations a full analytics package can provide a full pressing signature to ensure your parts are built to spec.

Available Through:

Semi-Automatic Production Lines

Hybrid cells from Guide Engineering pair human dexterity with robotic consistency: operators load fixtures while robots handle welding, pressing, or inspection under light-curtain protection. This modular approach doubles throughput compared to manual benches without the capital of a full transfer line. Stations can be upgraded to fully automatic operation later, safeguarding your initial investment.

Available From:

Leak & Functional Testing

Guide Engineering builds in-line test modules that apply air, vacuum, or hydraulic pressure while monitoring flow, decay or pressure drops. Additionally we have provided torque-to-turn, dynamic backlash, Anti-Lock Brake (ABS), and high precision gages. We can also provide functional test machines putting your production part in working position to test the assembly prior to leaving your facility. Test results can stream directly to MES for part-level traceability, triggering automatic reject diverters if specs aren’t met.

Available From:

Tooling/Fixturing

Precision nests, rotary positioners, and modular quick-change plates lock parts in exact orientation and shorten setup to minutes. Hardened datum surfaces resist wear across high-volume cycles, and optional RFID tagging or smart nesting links each fixture to its digital twin for automatic program recall. This tooling strategy underpins repeatable quality, whether the process is welding, machining, or final inspection.

Available From:

Manual Welding Productivity Solutions

The Swivel Arc™ boom transforms crowded weld bays into safer, higher-output cells. With a 33 ft aluminum (66 ft dia.) and 45 ft steel reach, welders work push-pull-gun-free; tapered bearings let you set joint “stiffness” for smooth rotation. Typical results: ~30 % more parts, fewer trip hazards, and less operator strain. Popular add-ons—like the portable base and pneumatic feed-assist—improve arc starts and extend conduit life. A Louisiana plant says the boom “reshaped our process,” enabling fewer welders and fewer footsteps while shipping more product.